Electroforming and electroplating have been used for a long time and it was used for different reasons. Its first potential was seen in the industry where it played a role as a material strengthener and protector. Every material that was either electroplated or electroformed had increased durability and it could withstand the material fatigue a lot better.

With newer technologies, industrial use grew to another level and now it is a highly precise process of growing metal that has almost no seems and it is highly durable. With advanced needs in the medical industry, airplane and aerospace industries these technologies found a new place and are now more valued than ever.

Source: refractorymetal.org

What also came from this is used in the jewellry industry where you can, using these techniques, make unique jewellry and even preserve organic material. It grew in this industry and copper and nickel plating are the most popular. You can plate almost anything as long as you have the equipment and you know the techniques and order it needs to go through.

As far as equipment is concerned places like Custom Microwave offer, although industrial grade, but high-end machines that use these techniques. The process of either electroplating or electroforming is as important as the machine that mixes everything and keeps it all under control, which means that guessing game in these processes is out of the question.

Now to return to the topic at hand. What is exactly electroforming and electroplating and what is the difference between them?

Electroplating

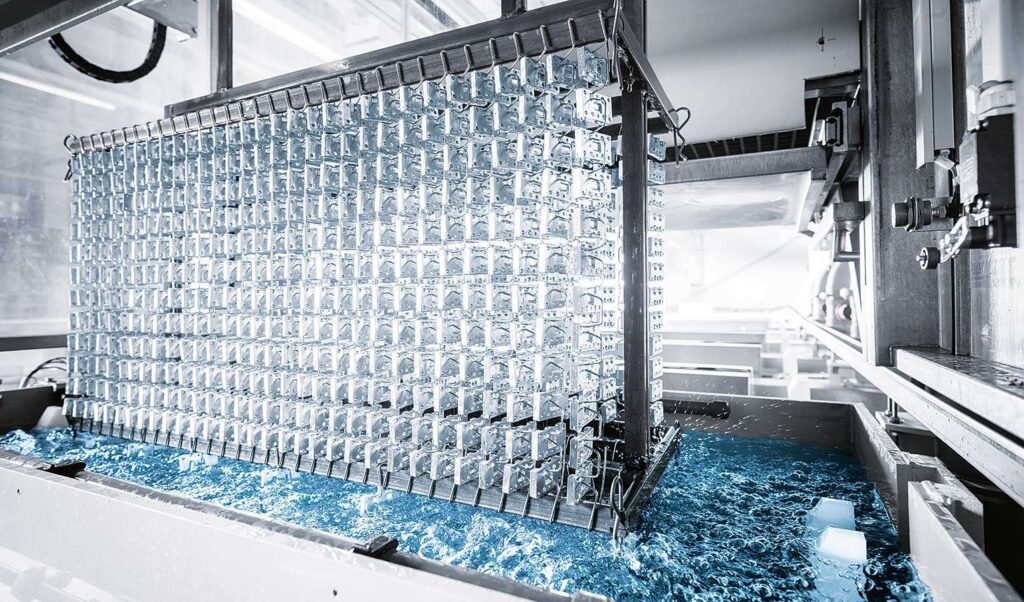

Source: festo.com

The simplest explanation possible is that electroplating is coating one metal with another. To do just this there is another thing necessary and it is electrolysis. Electrolysis is a process that uses electricity to drive a certain chemical reaction.

Metals are electroplated for several reasons and those are aesthetics, protection, or both. With aesthetic, you are making one metal shinier or giving it a more attractive color by coating it with another metal. Protection, on the other hand, is used when you want to protect a certain metal from corrosion, rust, or to simply lower its general wear and tear levels.

The process of electroplating starts when a current is passed through a solution that conducts electricity. To create a current, you have to have electrodes (anode and cathode) inserted into the solution and connect it to a power source. One thing to keep in mind is that you have to choose electrodes and electrolytes very carefully, and it has to be chosen based upon what metal you are plating with.

The speed at which this process occurs depends on the strength of the electric current. This translates to more power more speed at which ions and electrons move through the circuit and with that speed up the plating process. It is also important to choose your metals carefully for this process because not all metals will alloy with each other. An example of that is steel.

It first has to be copper plated to successfully silver-plate it, because metal and silver will not form a direct alloy with each other.

Electroforming

Source: adamas-japan.co

This process is derived from electroplating and it stands for an additive manufacturing process specialized for the production of high precision metal parts, as we noted at the beginning. This process has six steps to it and from beginning to end you have to go through:

- Cleaning – this means that you have to thoroughly clean and degrease the conductive metal substrate.

- Coating – is the next step and here the already cleaned metal substrate is coated with a light-sensitive photoresist.

- Exposing – is the third step that means this coated metal sheet is then exposed to ultraviolet light. With technology development, traditional photo tooling is replaced by LDIs or Laser Direct Imaging that is far more accurate.

- Developing – after the desired image has been transferred to the metal sheet by the UV light the substrate is then developed, rinsed and dried.

- Deposition – here we use an electrolytic bath to deposit the metal on the patterned surface to form what we intended. This process is pretty much the same as with electroplating (you have an electrolytic solution, two electrodes and a DC-current flowing through.) With DC-current converting ions into atoms we have a buildup on the cathode surface through a continuous deposit.

- Harvesting – in this last part the electroformed part can be harvested after you plate it to the desired thickness.

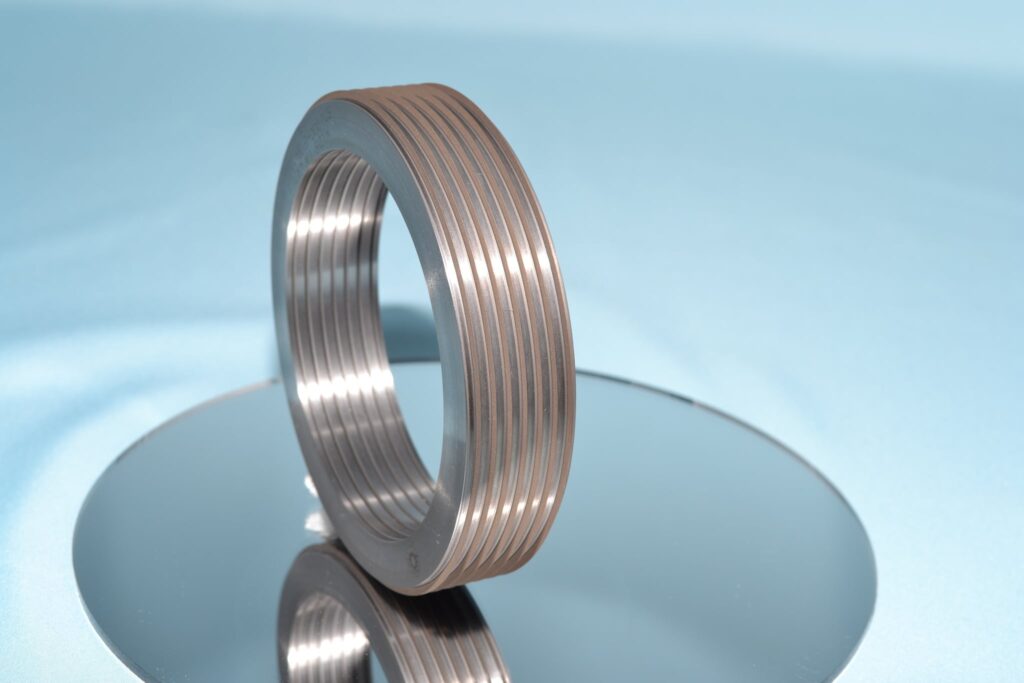

Source: heimerle-meule.com

So, as we already said this is pretty much the same process the electroplating, but the only difference here is that you create a part that you want using coating, exposition and developing steps, and as a final step you dip that into an electrolyte bath and hold it there for as long as you need, or until you reach the desired thickness.

This process is used in areas where joints are not welcomed and where you need certain metal thicknesses that are up to specific standards. It a highly controlled process and it can be done by professional machines. Electroplating is somewhat easier to DIY while this is highly precise and does not stand for any eyeballing. Do you know about the Transducer? If not then visit gmw.com

Electroforming is also famous in the jewellery business because it leaves a lot thicker coat of metals and it has a somewhat more abrasive surface. It can be used if you want to create a piece of art or a piece of jewellery that calls for a thicker surface with more texture. One thing to note, at least when it comes to using these processes in jewellery is that electroplating is what you will use if you want smoother surfaces and to hold on to more details. Electroforming on the other hand is a lot thicker, loses a lot of details but is a bit more robust and has a certain appeal to the finished product.

You also have to know that here you can mix these two and achieve something incredible. After electroforming is done and you have a piece that is thick and has that rougher texture, you can afterward dip it in the electrolysis bath and electroplate it to get a shinier finish layer with smoother textures and enhanced details.