When it comes to industrial flooring, it’s safe to say that there aren’t that many options. You need sturdy, easy to clean and maintain floors, non-slippery, non-conductive, non-flammable, so on and so forth. That leaves you pretty much down to only a handful of possibilities, namely concrete, steel or GRP grating. No wood or tiles in this conversation as they’re rather easily damaged.

Now, concrete and steel have been the primary solutions for quite some time and although there aren’t a lot of bad things anyone can say about them – there is always room for improvement. That’s where GRP grating enters the scene. If you’re unaware of GRPG, what it is, what it does or what it stands for, don’t worry, we’re about to get to that in just a moment.

What we want to talk about today, are the reasons why someone would switch to GRP grating instead of steel grating. In the following of this article, we’re going to touch on more than a few things and hopefully, by the end of it, you’ll understand why the steel grating is the inferior option in this instance. Now, without further ado – let’s get started.

What Is GRP Grating?

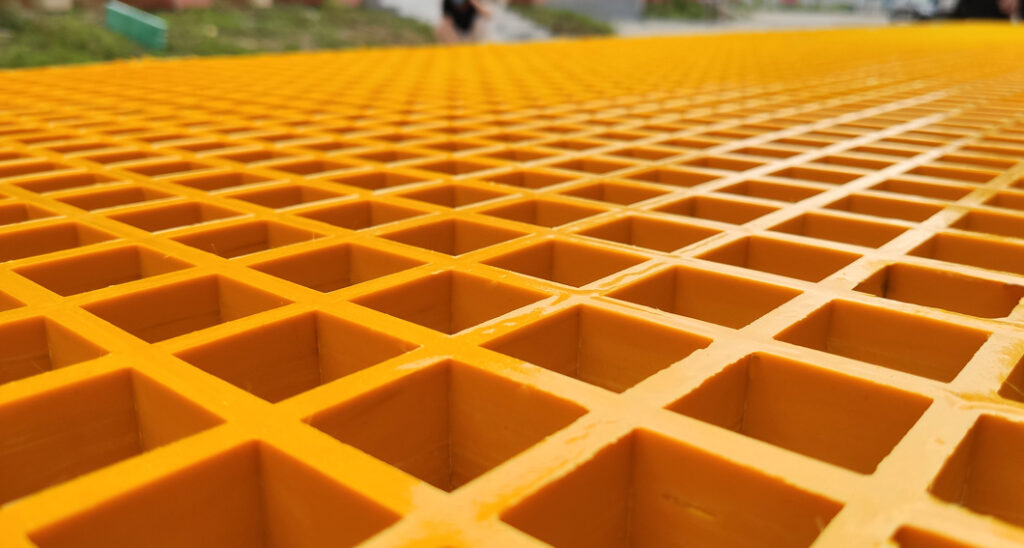

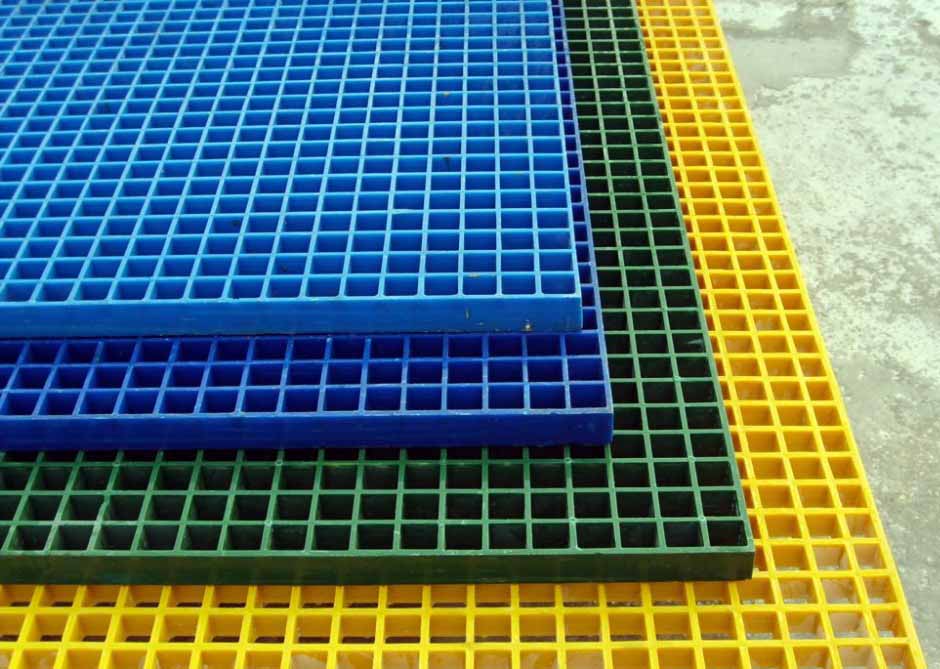

GRP (glass reinforced plastic) or FRP (fibreglass reinforced plastic) grating, however you want to call it, is a composite material made out of a mixture of resin and fibreglass. This material has an array of uses, but the most common one, and the one we’re interested in today, is industrial flooring, walkways and overhead platforms. In addition to that, this material is often used to manufacture protective shielding, machinery housings, raised flooring and stairways. It’s pretty clear that the main feature of FRP is to bear the load and allow others to safely walk on it.

Why Choose GRP Grating Over Steel Grating?

Since we’re basically looking to explain why anyone should switch from steel to fibreglass reinforced plastic, we have to do a little bit of a head-to-head battle. We have to go through some of the main features these materials bring to the table and see how well they stack up against each other. We’ll be objective during this battle of the titans as it is our duty to present the real information and not be biased in any way. With that out of the way, let’s get started.

1. Corrosion & Impact Resistance

Source: made-in-china.com

If we’re talking about a heavy industrial setting, we have to consider these two things first – corrosion and impact resistance. To say that the flooring is going to take the abuse is an understatement. The industrial environment is harsh – there are heavy machinery, chemicals, loads of people constantly moving about and so on.

One of the greatest strengths of glass reinforced plastic is the fact that it’s non-corrosive. That means it will not rust, or in any other way, suffer from water/air damage or any other kind of liquid or gas-induced wear and tear. As is the case with the fibreglass itself, this material requires little, to no maintenance, to keep in good shape.

In addition to being rust-proof, the structural integrity of this material is on another level. This material is, at the same time, touch and sturdy, as well as flexible. All of these put together means that you could drop a substantially heavy object on the floor and the floor would stay intact. What would happen to a dropped object – we don’t know. But, at least you’ll know your floor is still in great shape.

On the other hand, as we all know, one of the properties of steel is that it is tough and corrosion-prone to a certain level. It won’t go brown as the regular metal, but it will deteriorate over time. Also, steel can sometimes be too tough for its own good, so if you drop something very heavy on it, it won’t break, but it will permanently deform.

2. Strength & Weight

Source: nov.com

Obviously, fiberglass is lighter than steel, therefore, you can expect GRP grating to be lighter than the steel one. What you may not know is that it is almost 80% lighter than its steel counterpart. This, according to grpgratingsystems.co.uk, allows for much easier installation, manufacturing and transportation processes.

Now, when it comes to strength, resistance or just general toughness, they’re pretty much on par when it comes to those feats. Both steel and GRP can withstand a lot of applied pressure and they don’t break easily in any way, however, the fact that the FRP is doing it at a much better weight profile makes it a clear winner once again.

3. Non-Slippery Surface

Source: webforge.com.au

It is kind of common knowledge that a large portion of the accidents that occur during work hours are the results of slippery floors. That’s why you see those cautions signs on every corner. Now, for businesses – slips and trips mean lawsuit and as a business owner you don’t want those, we’d assume. Now steel grating floorings have a buttery smooth finish, which means that they can get quite slippery if you, say, spill some kind of oil over it.

On the flip side, if you’ve ever touched a fibreglass surface before, you noticed how in spite of being perfectly smooth, it’s still has a grippy and sticky feel to the touch. That’s because the material itself has great anti-slip qualities, which makes this one ideal for flooring, as it will lower the chances of accidents to almost zero.

4. Cost

Source: gratinguae.com

As far as the initial cost is concerned, steel gratings take the W here, as it is cheaper to obtain and install in the first place. However, when we take life-expectancy of these materials and compare the maintenance costs over the years, which in the case of a GRP grating is about 50, we end up with a completely different picture.

GRP not only has a longer life-span, it is also far cheaper to maintain, as we’ve mentioned before. That means, that in the long run – GRP grating is not only a better investment overall, but it will also be a better decision expense-wise.

As you can tell, glass-reinforced plastic grating wins this one by a landslide. It is fairly obvious who’s the clear winner here and we haven’t even touched on the versatility, UV stability and other neat features of an FRP grating.

Hopefully, this has been informative and you now know, without a doubt, which of the two is a better bang for your buck.